| Type | Specification |

|---|---|

| Material | Unbleached Kraft Paperboard, Recycled Kraft Cardstock, Corrugated Kraft (Single Wall / E-flute) |

| Coating Options | Grease-resistant aqueous coating, Food-safe PE lining, Uncoated natural matte finish |

| Printing | CMYK, PMS spot colours, Flexographic or Offset printing, Digital mockups available |

| Logo Customisation | Full logo print, debossing, embossing, foil stamping (gold/silver/copper) |

| Colour Options | Natural kraft brown, black kraft, white ink print, or full-colour CMYK over kraft base |

| Sizes Available | Custom sizes for regular, large, XL, or double-patty burgers; adjustable depth & width |

| Closure Styles | Clamshell, Tuck Top, Tab Lock, Slotted Flap or Custom Die-Cut Closure |

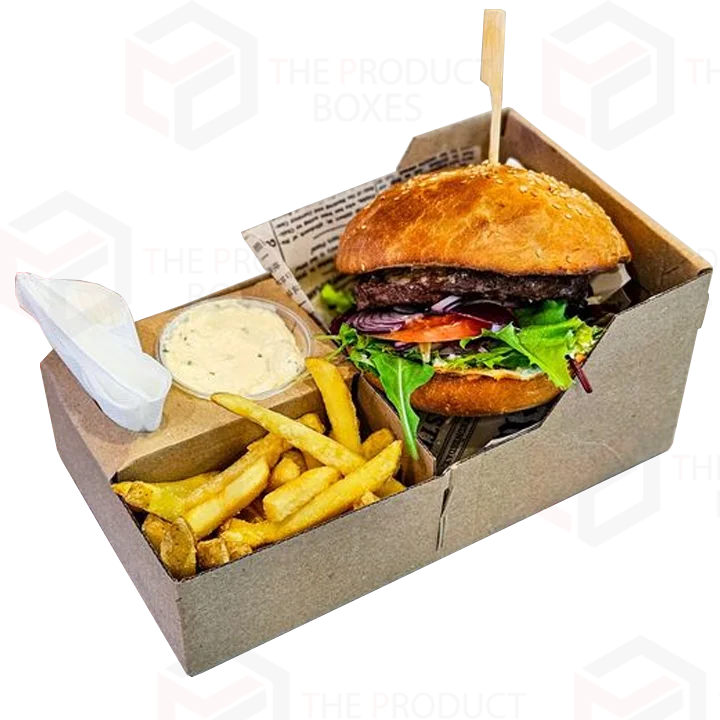

| Insert Options | Custom cardboard inserts for fries, sauces, or burger compartments |

| Eco Certifications | FSC Certified, Compostable, Recyclable, Biodegradable |

| MOQ | Minimum 100 boxes per design, wholesale bulk available |

| Sample Options | Digital proof and physical prototype before production |

| Finishes | Matte, Gloss, Soft Touch, Kraft Texture, Spot UV |

| Use Case | Takeaway, dine-in, delivery, event catering, food trucks |

| Lead Time | 7–12 business days post artwork approval; rush production available |

Kraft Burger Boxes

Burger pakaging becomes sustainable and stylish when you use kraft burger boxes as a brand-identified presentation offered by TPB UK. The sustainable boxes work great for food trucks, organic eateries and fast food points as they offer both rustic natural aesthetics and high performance at work. The Product Boxes UK manufacture custom heat-resistant brown paper burger box that function effectively under all handling conditions. Customers can select from mu;tiple sizes and styles of boxes which combine custom logo printing with brand-specific artwork for personalised branding.

The combination of sustainability with excellent strength retention allows kraft boxes to work perfectly for food delivery. You can find the box with rustic branding from our selection of options to choose from. At The Product Boxes, we offer kraft burger boxes for bulk orders at affordable wholesale prices with no compromise on quality standards. Contact us today to order customised burger boxes that match your business principles while making a memorable customer experience.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Kraft Burger Boxes?

Q. Are Kraft Burger Boxes suitable for greasy and hot burgers?

Q. Can I customise Kraft Burger Boxes with my brand logo?

Q. Do Kraft Burger Boxes come in different sizes?

Q. Are Kraft Burger Boxes eco-friendly?

Q. What closure styles are available in Kraft Burger Boxes?

Q. What type of finishes can I apply to my Kraft Burger Boxes?

Q. Do you provide samples before placing a bulk order?

Q. What is the minimum order for custom Kraft Burger Boxes?

Q. What is the turnaround time for Kraft Burger Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.