| Type | Specification |

|---|---|

| Material Structure | Multi-layer PET/VMPET/PE with optional aluminium foil barrier |

| Bag Style | Stand-up pouch, flat pouch, 3-side seal, ziplock, gusseted |

| Closure Options | Resealable zipper, heat seal, tear notch, child-resistant zip |

| Finish | Gloss, matte, soft-touch, holographic, UV spot, metallic foil |

| Custom Logo | Yes – digital, rotogravure, or flexographic printing supported |

| Colour Options | Full CMYK, PMS colour matching, custom spot colour printing |

| Size Range | Standard sizes (2×3″, 3×5″, 4×6″, etc.) – We offer fully custom sizes |

| Thickness | 2.5 mil to 7.0 mil (custom thickness based on product type) |

| Barrier Properties | Excellent protection from oxygen, moisture, UV light, and odours |

| Quantity | MOQ 500 units – bulk and wholesale quantities available |

| Food Grade | Yes – manufactured with FDA-approved, food-safe materials |

| Eco-Friendly Options | Available – recyclable, biodegradable, and compostable materials |

| Applications | Dried mushrooms, spores, medicinal blends, powders, capsules |

| Print Capability | Up to 10-colour HD printing – edge-to-edge, custom branding |

| Certifications | FDA, BPA-free, ISO 9001 – compliant for global standards |

Mushroom Mylar Bags

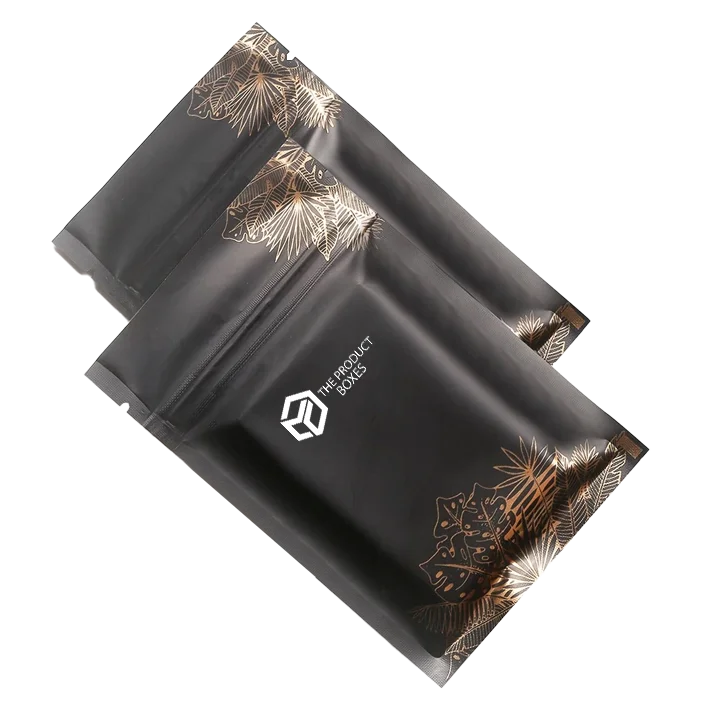

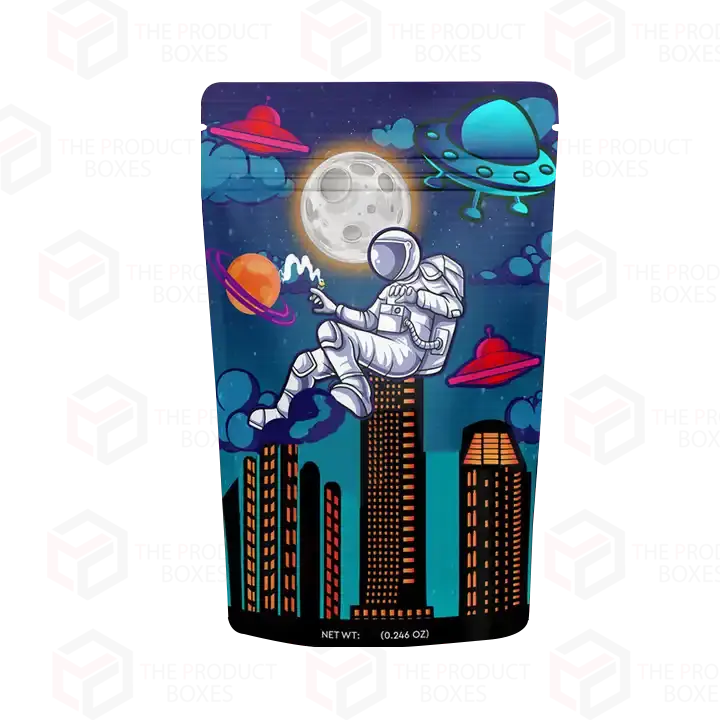

Mushroom Mylar bags from The Product Boxes UK serve as an ideal container for safe mushroom storage. High-barrier lightweight bags help keep dried mushrooms, supplements and infused edibles fresh by blocking out light, air and moisture which preserves their potency as well as their shelf life duration. Mylar film in its food-grade configuration becomes the base material for our bags which combine smell-proofing and tamper-proof design. Our mushroom packaging bags preserve resealability to maintain content security and discreteness. Users who need packaging for functional mushrooms or varieties for legal markets, all will benefit from our protection-focused packaging solution featuring impactful branding elements.

Get custom printing services from The Product Boxes UK and print your custom edible mylar bags with colours, necessary labels, branded logo and product details. The product line and branding match best when you select from multiple sized Mylar bags with finishes including matte, gloss, metallic and holographic. Our company provides mushroom Mylar bags that work for retail stores and wholesale businesses featuring rapid manufacturing schedules with bulk purchase incentives. We invites you to get personalised mushroom Mylar bags for product enhancement and extended shelf life.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Mushroom Mylar Bags?

Q. Are Mushroom Mylar Bags food-safe?

Q. Can I get custom sizes for Mushroom Mylar Bags?

Q. Can I print my own logo and design on Mushroom Mylar Bags?

Q. What closure options do Mushroom Mylar Bags offer?

Q. Are these bags suitable for long-term mushroom storage?

Q. Can I order small quantities for a test run?

Q. Do you offer eco-friendly options for Mushroom Mylar Bags?

Q. Can I request a sample before placing a bulk order?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.