| Type | Specification |

|---|---|

| Material | Food-grade Kraft, SBS paperboard, corrugated cardboard, or recyclable cardboard |

| Printing | CMYK, PMS, digital, or offset custom printing options |

| Coating | Matte, Gloss, UV Spot, or Aqueous finish for moisture resistance |

| Logo Placement | Full surface branding with front, lid, or side panel logo application |

| Box Sizes | Customisable dimensions for single, double, or gourmet burgers |

| Box Style | Standard tuck-top, clamshell, or hinged-lid construction |

| Custom Inserts | Available with grease-resistant liner or compostable insert tray |

| Colours | Full-colour print (up to 4 colours), kraft brown, or custom Pantone shades |

| Quantity | Minimum orders from 500 units; bulk orders available up to 100K+ |

| Window Option | Optional PET or PLA transparent viewing window on lid |

| Eco-Friendly Option | Recyclable, biodegradable, or compostable stock available |

| Closure Style | Lock-tab, snap-shut, or die-cut lid for secure closure |

| Lead Time | Standard 7–10 business days production after artwork approval |

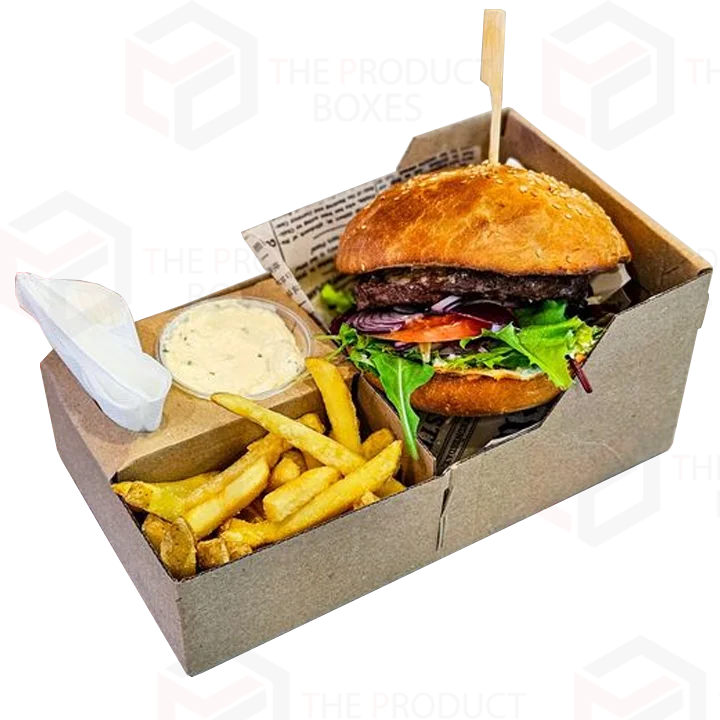

Personalised Burger Boxes

Your brand will stand out with personalised burger boxes which The Product Boxes UK offers. Cardboard boxes are perfect for restaurants, food trucks, cafes and takeout services as they provide protection for your delicious burgers with superior brand display capacity. High-quality food-safe cardboard and kraft materials form durable personalised burger boxes which assemble quickly and reveal professional packaging appearance. Each box is fully customisable with your brand-specific logo, colours, texts and graphics for creating a powerful visual presence.

Businesses can maintain fresh hot and whole burgers by using our custom printed burger boxes which contain grease-resistant features as well as ventilation holes with secure closures. These boxes serve customers by properly containing any burger type that you offer from classic to gourmet as well as vegan versions. Our company provides burger boxes wholesale prices, along with personalised dimensions and fast order completion to serve businesses of every scale. So, don’t wait and contact TPB to enhance your brand while delivering extraordinary dining experiences.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Personalised Burger Boxes?

Q. Can I print my restaurant logo and branding on the burger boxes?

Q. Are these boxes safe for hot and greasy food?

Q. What sizes are available for Personalised Burger Boxes?

Q. Are these boxes eco-friendly or recyclable?

Q. Do the boxes come with a window or special shape?

Q. Can I order in small quantities for a food truck or local event?

Q. How long does it take to produce custom burger boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.