| Type | Specification |

|---|---|

| Product Name | Personalised Poly Mailers |

| Material Type | Co-extruded polyethylene (PE) |

| Film Grade | LDPE / MDPE blend |

| Surface Finish | Matte, gloss, or soft-touch |

| Film Thickness | Custom micron range |

| Bag Structure | Single-layer or multi-layer film |

| Opacity Level | Opaque or semi-opaque |

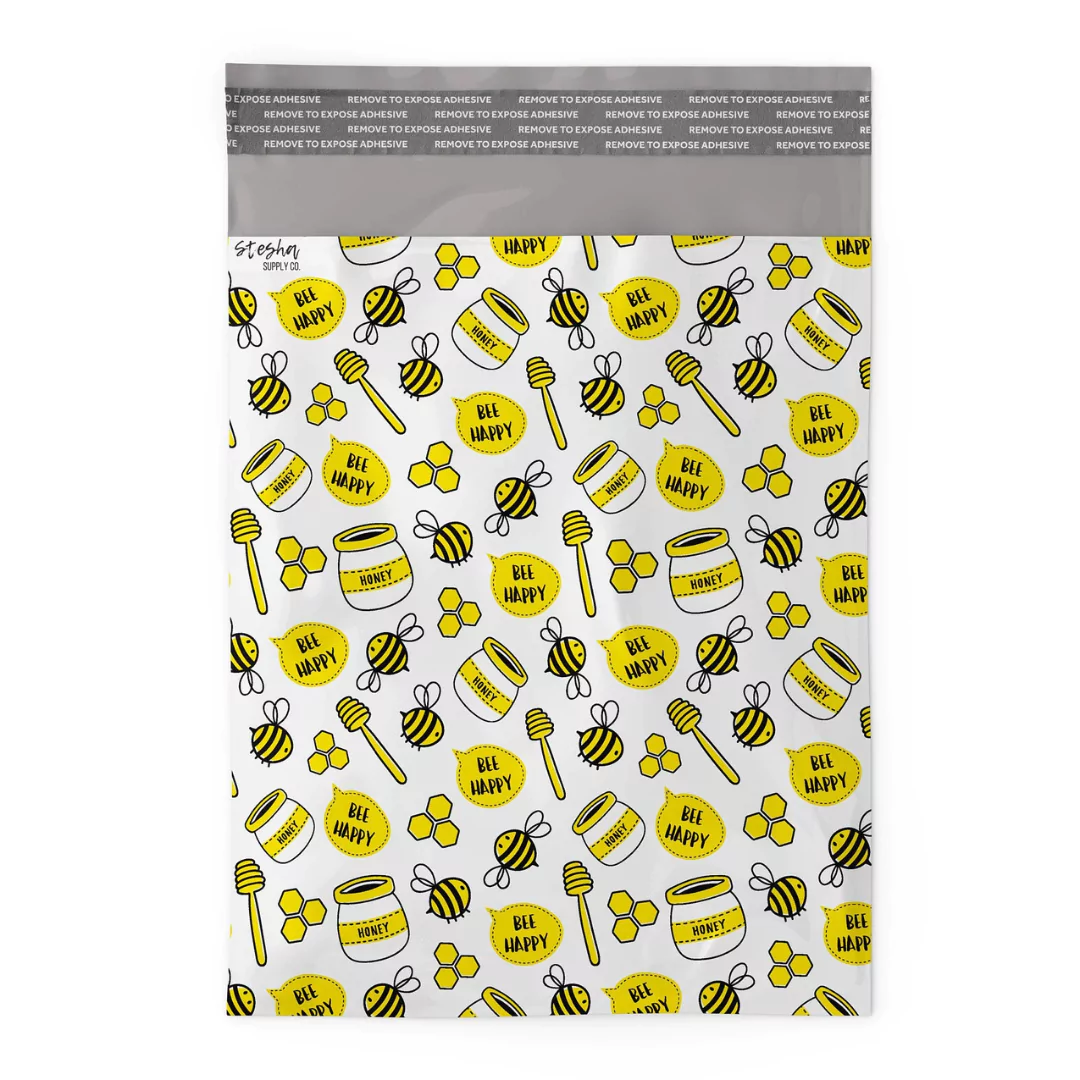

| Colour Options | Full custom colour matching |

| Size Options | Custom width and length |

| Flap Type | Extended sealing flap |

| Closure Method | Permanent self-adhesive strip |

| Adhesive Strength | Tamper-resistant hot-melt glue |

| Seal Type | High-strength heat sealing |

| Tear Resistance | High puncture durability |

| Water Resistance | Moisture and spill proof |

| Dust Protection | Fully enclosed barrier |

| Security Feature | Destructive seal on opening |

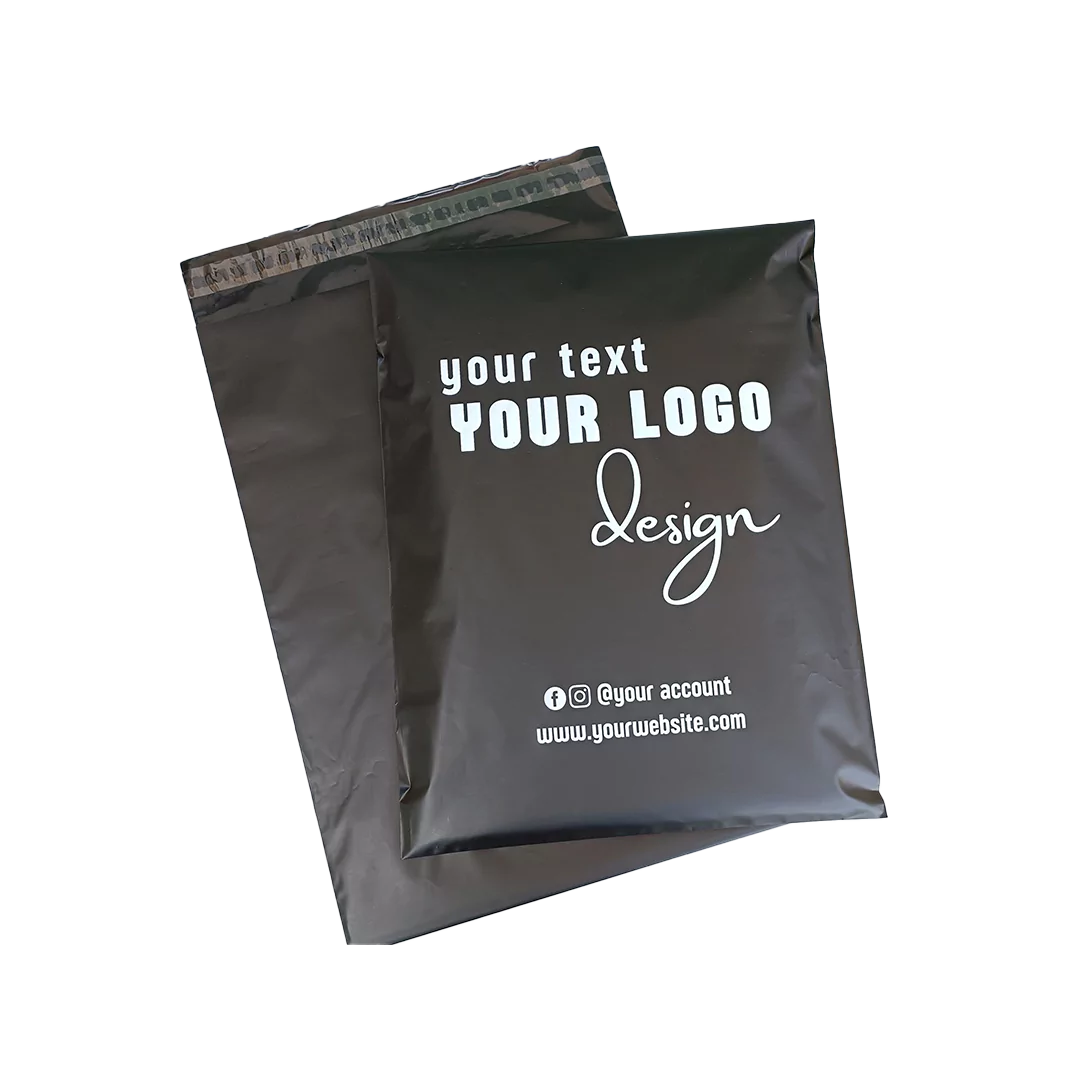

| Logo Printing | Custom brand logo printing |

| Printing Method | Flexographic or digital print |

| Ink Type | Smudge-resistant inks |

| Print Coverage | Single or double-sided print |

| Finish Options | Spot UV, matte, or gloss |

| Quantity Options | Short runs to bulk volumes |

| MOQ | Low minimum order options |

| Customisation Scope | Logo, size, colour, finish |

| Eco Options | Recyclable and eco-film grades |

| Manufacturing Process | Film extrusion and automated sealing |

| Quality Control | Seal strength and thickness checks |

| Packing Style | Flat-packed cartons |

| Primary Use | E-commerce shipping and returns |

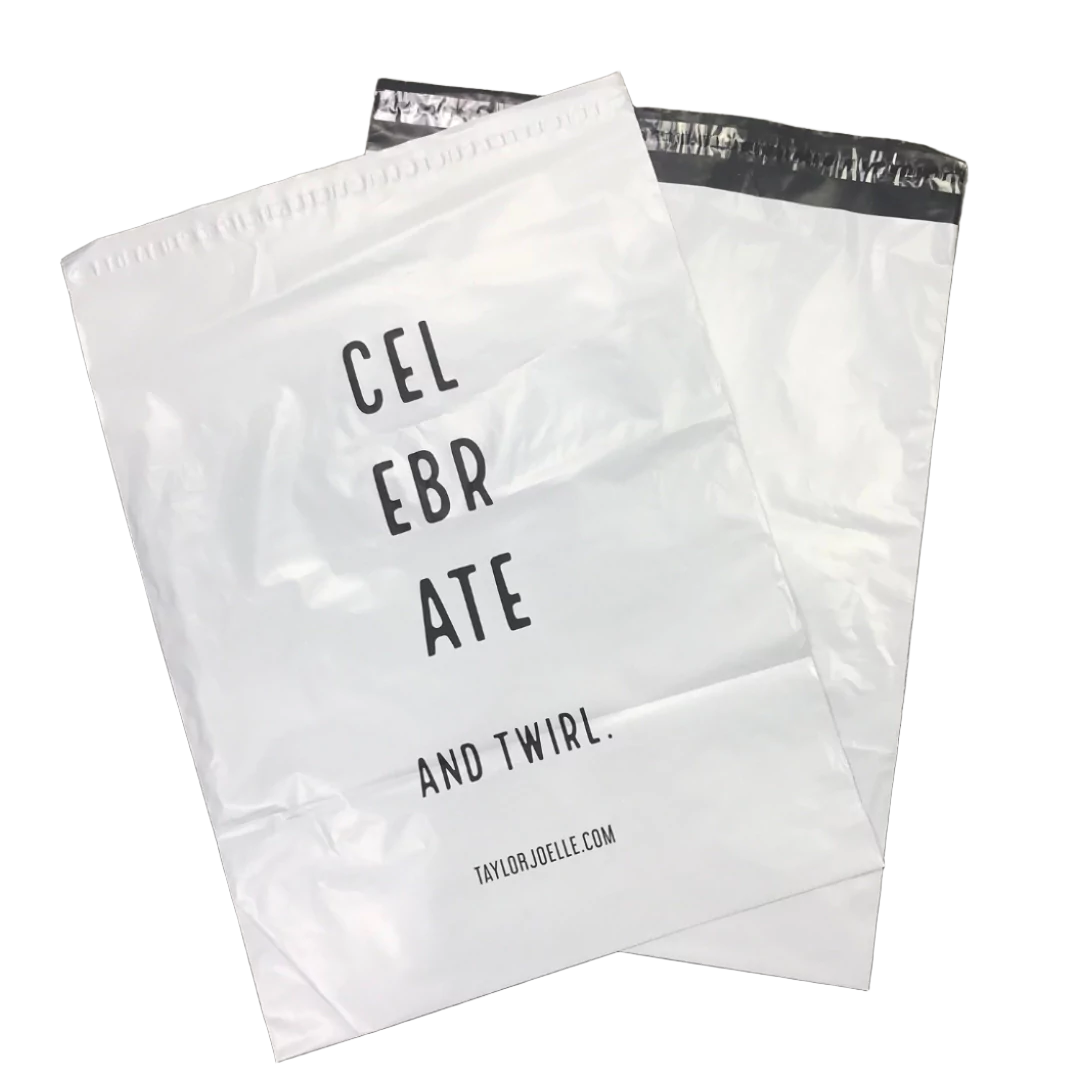

Personalised Poly Mailers

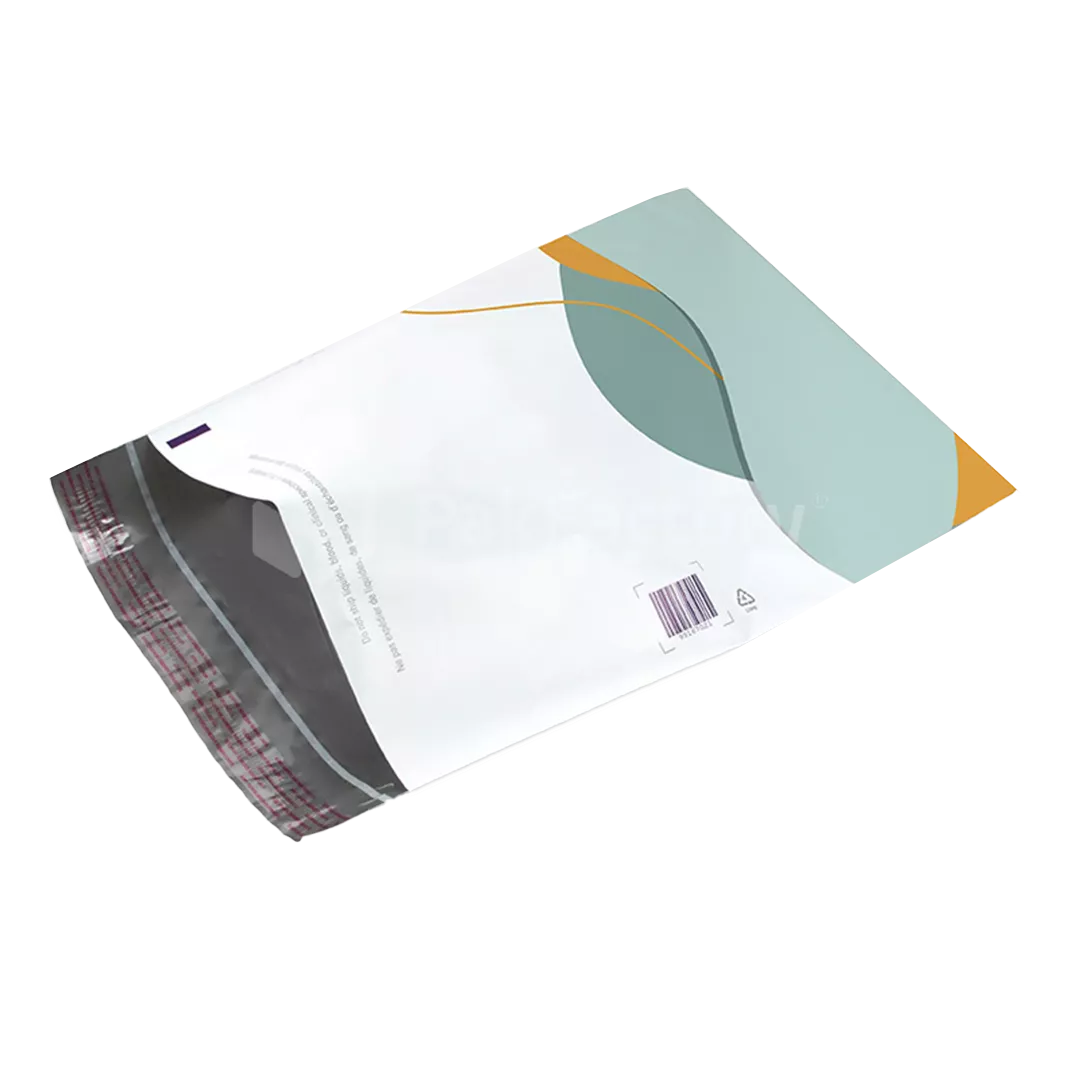

Stand out in customer mailboxes with personalised poly mailers featuring custom names, messages, or variable data printing that makes each package feel individually crafted. Perfect for subscription boxes, personalized gift services, and businesses building strong customer relationships through thoughtful packaging. Each mailer displays different recipient names or personalized messages while maintaining consistent brand identity across your entire order. The waterproof poly material protects contents during shipping with self-sealing strips that enable quick packing without additional tape. Available in standard e-commerce sizes with lightweight construction minimizing postage costs.

Customers photograph and share packages addressed specifically to them far more frequently than generic branded packaging, making custom mailers bags valuable for social media marketing and word-of-mouth growth. Ideal for monthly subscription services or special promotional campaigns where individual connection drives engagement. The Product Boxes manufactures personalised poly mailers with variable data printing handling thousands of unique variations within single production runs. Wholesale pricing applies even with personalisation across every unit. Design options include full-color graphics combined with personalized text. Production approximately three weeks with minimum orders accommodating various business sizes.

Starting From: £0.30 Per Box

Available in Stock

Q: What sizes are available for personalised poly mailers?

Q: Which material thickness is best for personalised poly mailers?

Q: Can personalised poly mailers be printed with logos or designs?

Q: Are personalised poly mailers suitable for e-commerce shipping?

Q: Can personalised poly mailers be resealable?

Q: Are eco-friendly personalised poly mailers available?

Q: How are bulk orders of personalised poly mailers packaged?

Q: What printing tolerances should buyers expect on personalised poly mailers?

Q: Can personalised poly mailers be used internationally?

Q: How does colour choice affect branding on personalised poly mailers?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.