| Type | Specification |

|---|---|

| Material | Food-grade SBS board / PE-coated paperboard / Kraft linerboard |

| Structure | Round wall construction with rolled rim and leak-proof base |

| Coating | Single or double PE coating for moisture and grease resistance |

| Printing | CMYK, Pantone, or full-colour offset printing with matte/gloss finish |

| Branding Options | Custom logo, artwork, embossing, foil stamping, or UV spot coating |

| Standard Sizes | 16oz, 32oz, 46oz, 64oz, 85oz, 130oz, with custom volumes available |

| Height Range | 80mm to 210mm depending on bucket volume |

| Diameter Range | 90mm to 200mm (top), tapering to 70mm to 160mm (bottom) |

| Colour Options | White, kraft brown, or custom Pantone shades |

| Lid Option | Optional PET dome lid or paper lid (vented or sealed) |

| Usage | Popcorn, nachos, fries, snacks – cinema, event, concession use |

| MOQ | Starting from 1,000 units (depends on customisation) |

| Eco Option | Available in recyclable kraft and biodegradable coated board |

| Lead Time | 7–10 business days after design approval |

| Customisation | Full custom sizing, shape, print, and interior coating available |

Round Popcorn Bucket

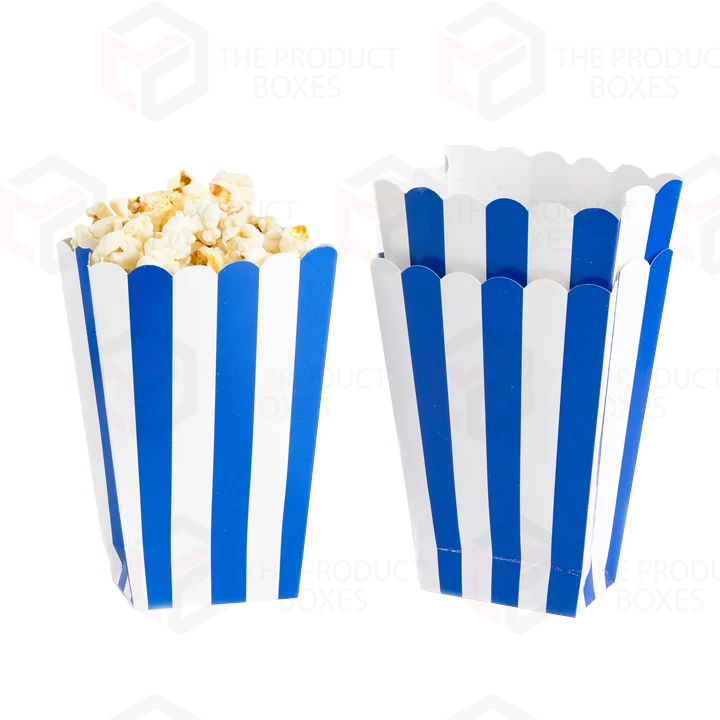

Round popcorn bucket creates unforgettable movie parties with other events. These serving containers from The Product Boxes UK provide an elegant solution for holding popcorn and other snacks at theatres, festivals, food vendors and special occasions. The round buckets are food-safe made of high-quality cardboard or paperboard materials to serve both buttery and dry snacks without leaking or shape degradation. The big printing surface allows customers to add their branding through dynamic and premium quality designs.

Customers can select different bucket sizes, finishes and designs, accommodating individual portions and family-size portions. Moreover, the addition of glossy and matte coatings with colourful designs give an unforgettable snacking experience. Round shape popcorn buckets serve events including cinemas, sports spectacles, parties as well as branded promotions through custom printed popcorn boxes with fast deliveries and minimal order requirements. At TPB UK, we offer customisable popcorn buckets that unite taste sensation, entertainment, quality and branding impact in each serving.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Round Popcorn Buckets?

Q. Can I customise Round Popcorn Buckets with my logo and branding?

Q. What are the available sizes for Round Popcorn Buckets?

Q. Are these buckets leak-proof or grease-resistant?

Q. Are lids available with Round Popcorn Buckets?

Q. Can I order eco-friendly or recyclable popcorn buckets?

Q. What is the minimum order quantity (MOQ) for customised Round Popcorn Buckets?

Q. How long does it take to produce custom Round Popcorn Buckets?

Q. Can I request a sample before placing a bulk order?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.