| Type | Specification |

|---|---|

| Product Name | Small Mylar Bags |

| Material | Multi-layer laminated Mylar (PET/AL/PE or PET/PE) |

| Barrier Properties | High moisture, oxygen, and UV resistance |

| Customisation | Full custom printing with matte, gloss, or holographic finishes |

| Logo Printing | Custom logo in CMYK, PMS, spot UV, or foil stamping |

| Colour Options | Standard brown, silver, black, white + fully custom colours |

| Sizes Available | 2×3″, 3×4″, 4×6″, 5×7″, 6×9″, or custom die-cut dimensions |

| Closure Type | Zip lock, heat seal, or tear notch with optional hang hole |

| Bag Thickness | 2.5 mil to 5 mil (single side) — available in custom gauges |

| Surface Finish | Gloss, matte, soft-touch, or metallic sheen |

| Eco-Friendly Options | Recyclable, biodegradable, or compostable films upon request |

| Printing Techniques | Digital, rotogravure, or flexographic up to 10 colours |

| Inner Coating | Food-grade aluminium or polyethylene (PE) lining |

| Quantity | MOQ starts from 500 units — bulk available |

| Use Cases | CBD, snacks, herbs, spices, cosmetics, small electronics |

| Lead Time | 7–12 business days (varies with customisation level) |

| Certifications | FDA compliant, BPA-free, RoHS, and ISO 9001 certified |

Small Mylar Bags

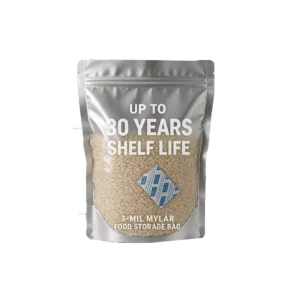

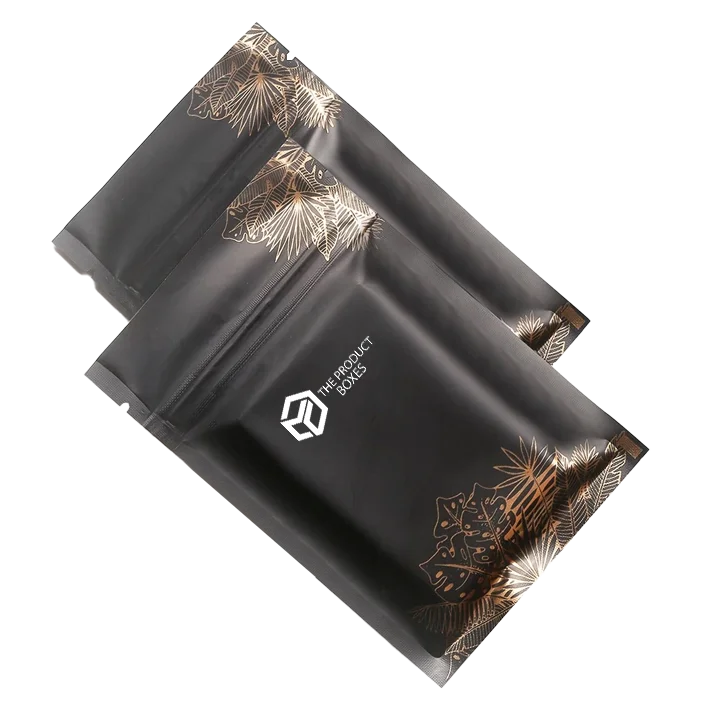

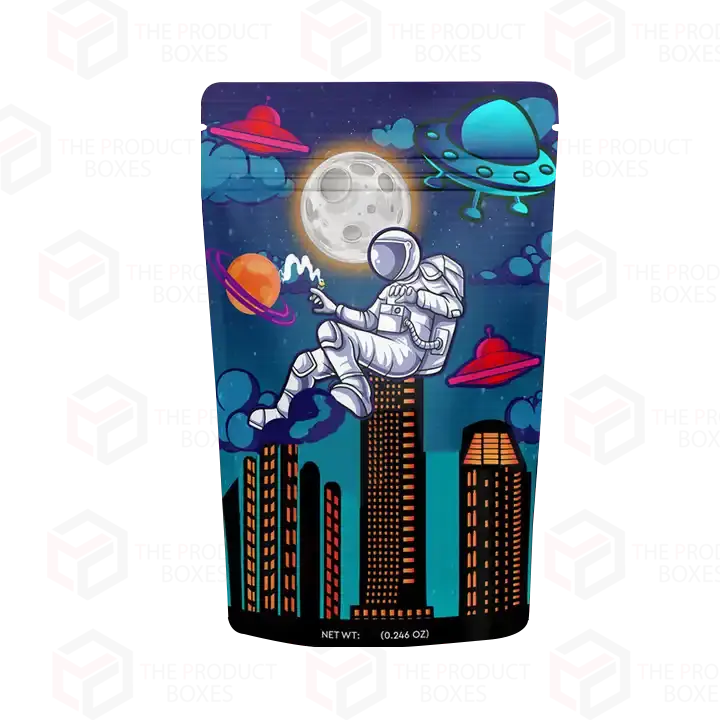

Small mylar bags at The Product Boxes UK maintain fresh and protective product packaging. The high-barrier bags work well for herbs, spices, snacks, cosmetics, supplements, seeds and small packets by providing extended shelf life due to their resistance to moisture, light and oxygen. We offer custom size mylar bags with multiple dimensions, gloss, matte, metallic and holographic options. We allows the customers to design your own mylar bags with different design choices. Our product range features resealable zip-lock closures, heat-seal tops, tear notches, stand-up and flat pouch designs to provide top user convenience.

Custom printing options enable you to add your logo or branding information to achieve a professional finished product. Small Mylar bags from our company serve as cost-effective packaging solutions which offer secure storage for retail requirements, sample distribution and personal collection. Get mylar bags wholesale uk with minimal order requirements and expedited production time as well as complete design assistance. Contact us now and get mylar packaging bags which protect your products and boost their brand image.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Small Mylar Bags?

Q. Are Small Mylar Bags food safe?

Q. Can I customise the design of Small Mylar Bags?

Q. What sizes are available for Small Mylar Bags?

Q. What type of closures do Small Mylar Bags offer?

Q. Are Small Mylar Bags eco-friendly?

Q. How many Small Mylar Bags can I order?

Q. Can I request a sample before placing a bulk order?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.