| Type | Specification |

|---|---|

| Product Name | White Burger Boxes |

| Material | Food-Grade SBS Paperboard / Kraft Liner / Corrugated Cardboard |

| Colour Options | Standard White / Custom CMYK / PMS / Pantone Shades |

| Printing Techniques | CMYK / PMS / UV Printing / Flexo / Digital / Offset |

| Surface Finish | Matte / Gloss / Soft-Touch / Anti-Scratch / Aqueous Coating |

| Logo Placement | Front, Top Lid, Inside Lid, All Sides (Customisable) |

| Closure Style | Clamshell / Tuck-Top / Snap-Lock / Tab Lock |

| Box Sizes | Custom Sizes (Regular, Large, Jumbo, Double-Patty Fit) |

| Thickness | 12pt, 14pt, 16pt, 18pt, 24pt Board |

| Grease Resistance | Oil-Resistant Coating / PE Lamination (Optional) |

| Eco-Friendliness | Recyclable / Compostable / FSC Certified |

| Usage | Fast Food Chains / Takeaway / Burger Joints / Events |

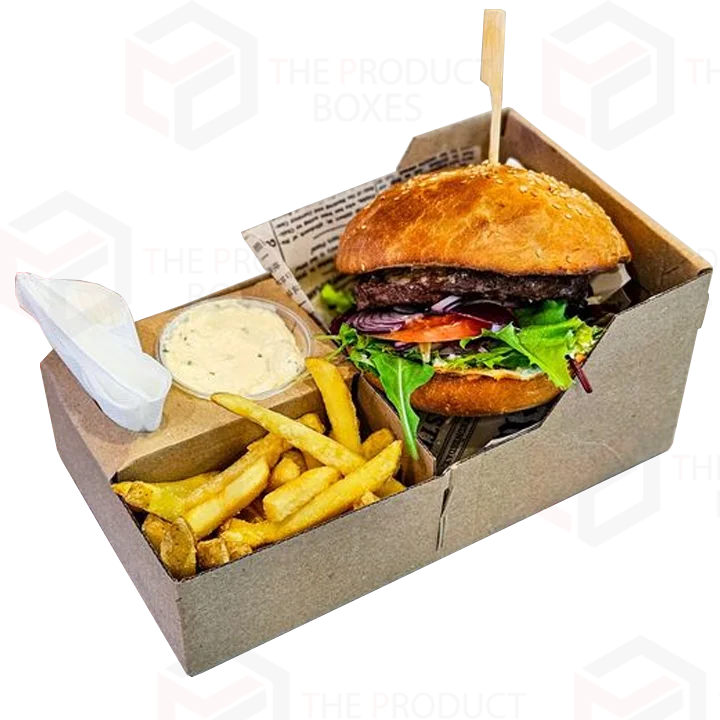

| Inserts | Optional Inserts for Fries, Sauces, or Combo Meals |

| MOQ | 100 Units (Custom Orders Accepted) |

| Customisation | Full Custom Branding, Size, Shape, and Style |

| Delivery Format | Flat Packed / Pre-Assembled (As Requested) |

| Lead Time | 7–12 Business Days (After Final Design Approval) |

| Sampling | Digital Mockups & Physical Samples Available |

White Burger Boxes

White burger boxes serve as an excellent packaging solution which presents your food products with distinctive modern and professional appeal. These neutral-coloured boxes serve gourmet, fast food chains, cafes and events because they amplify brand designs while delivering premium presentations. The Product Boxes manufactures personalised burger boxes made from high-quality food-safe cardboard that features grease resistance and environmental sustainability. Select from various sizes and styles to suit the menu requirements before adding logo printing and bold graphics for maximum impact.

Our white boxes act as the ideal foundational design for creating basic elegant or attention-grabbing brand-focused presentations. The packaging serves well for meals ordered by delivery as it maintains the burgers hot and safe from damage. Our business offers wholesale white burger boxes for businesses requiring bulk purchases through economical solutions. You can contact The Product Boxes now to order tailored burger boxes that will polish your packaging while making the brand easily noticeable in a competitive market.

Starting From: £0.57 Per Box

Available in Stock

Q. What materials are used to make White Burger Boxes?

Q. Are White Burger Boxes suitable for hot and greasy food?

Q. Can I customise the White Burger Boxes with my logo?

Q. Are White Burger Boxes available in different sizes?

Q. Are these burger boxes eco-friendly?

Q. Do you offer bulk quantities or wholesale orders?

Q. What type of printing finishes are available?

Q. Can I request a physical sample before bulk production?

Q. What closure styles are available for White Burger Boxes?

Q. How long does production take for custom White Burger Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.